By providing visibility across multiple modes of transportation, supply chain control towers help companies make key transportation and logistics decisions based on real-time data.

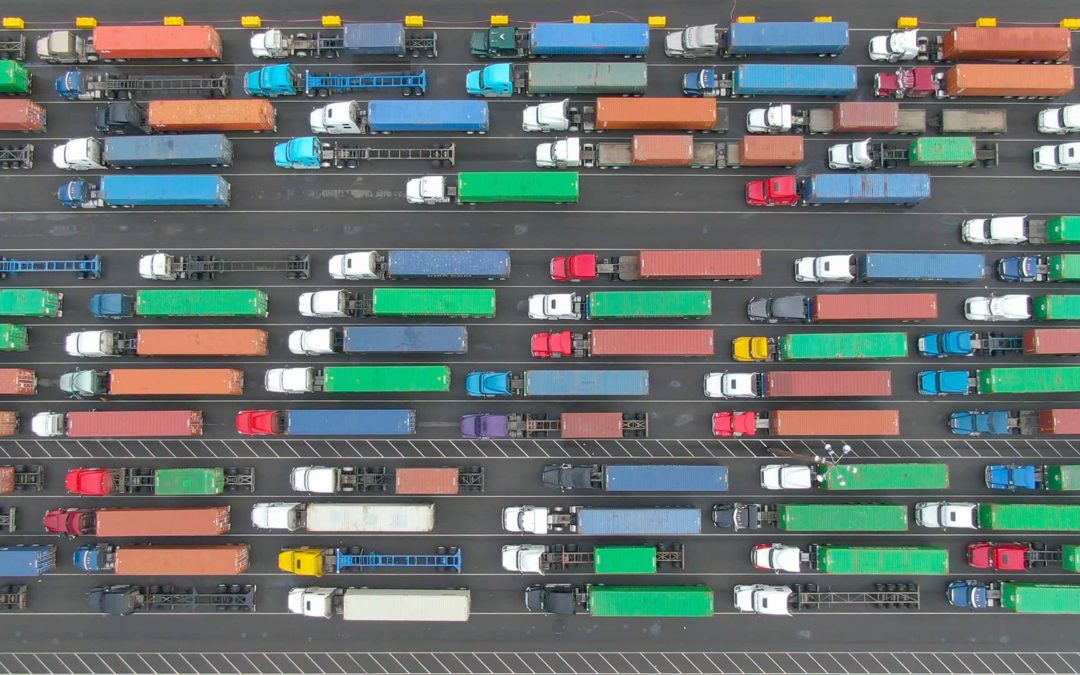

Every year, more than 10 billion tons of freight make their way across the nation’s highways, carrying about 73% of the total, primary domestic freight tonnage shipped. To carry these loads, industries rely on nearly 38 million trucks that are registered and used for business purposes (excluding government and farm), including almost 4 million Class 8 trucks (these include both tractors and straight trucks). Collectively, the trucks travel more than 300 million miles annually, consume roughly 46 billion gallons of fuel, and employ about 7.7 million people.

A critical aspect of the nation’s transportation infrastructure, trucking is also a key contributor to greenhouse gas (GHG) emissions and other environmental issues. Overall GHG emissions from transportation account for about 29% of total US GHGs, making it the largest contributor of such emissions in the US. Fortunately, technology has advanced to a point where it can help whittle away at trucking’s carbon footprint, reduce (or even eliminate) empty miles and give organizations more control over their transportation networks.

For example, companies can use supply chain control towers to minimize miles driven and improve environmental sustainability through transportation optimization. This has become a key focus during this period of volatility, where businesses are demanding more control over their supply chains. Using modern supply chain planning strategies that incorporate control towers, companies can more effectively visualize the end-to-end supply chain, stay abreast of issues and address them before they become real problems.

Reducing Deadhead Miles

When a driver drops off a load and travels to pick up another load, the distance in miles traveled are considered “deadhead miles.” These empty miles not only cost the carrier and/or driver money, but they also add to the trucking industry’s carbon footprint and give nothing in return.

In Technology Reduces Deadhead Miles, Improving Trucking Efficiency, NEXT Trucking’s Ashley Lewis points out that nearly 40% of trucks on the road today could be driving empty miles. “When a truck is traveling without a loaded trailer or shipping container the resulting fuel emissions produced during that trip are effectively wasted,” Lewis writes. “Despite the inefficiency of the process, it’s often a necessary component of the container cycle.”

Lewis says some of the newer technology solutions on the market are disrupting that “efficiency bottleneck.” For example, fleet owners can implement digital marketplaces or app-based mobile solutions to match empty containers at the warehouse with a company in need of a container for their exports. “As a result, the container can be delivered to a nearby warehouse, loaded with goods awaiting export, and returned to the port with a full load,” she writes.

“By using technology to facilitate these transactions or ‘street turns,’” Lewis adds, “fleet operators can support improved efficiency and reduce the needless carbon emissions produced by empty miles on the road.” Where a human dispatcher might not be able to optimize these processes with the same speed, accuracy and insight that a computer algorithm can, software can step in and help minimize deadhead miles, empty loads and other non-sustainable transportation moves.

Visibility Across Multiple Modes

Supply chain control towers can also help companies achieve the corporate environmental, sustainability and governance (ESG) goals that so many organizations, investors, customers and other stakeholders have their eye on right now. Studies show that 80% of consumers want more sustainable products, and want to buy from companies with sustainable business practices, which include emphasis on human rights and social issues across the supply chain, in addition to environmental concerns, Supply & Demand Chain Executive reports.

This combination of pressures means that companies really can’t afford to wait to act on these issues. “Even with logistics issues wreaking havoc on the supply chain, now is the time to implement strategies to meet ESG goals before policy and public pressure make it impossible to remain competitive,” the publication points out.

“By providing a real-time method for monitoring, measuring and reporting on key ESG metrics from across the entire supply chain,” SDCE explains, “a supply chain control tower gives companies broad visibility into their ESG performance so they can make decisions and adjustments to optimize operations.”

By using a supply chain control tower to tie into freight carrier systems, for example, companies can look at alternative routes for oceanic shipping and even onshore trucking to minimize travel. Or, companies can use these platforms to source alternative modes like planes and trains to make the long haul and use trucks only for last-mile delivery to reduce emissions.

“The control tower provides visibility across multiple modes of transportation,” SDCE adds, “to help companies make those decisions based on real-time data.”

.jpg)

IntelliTrans’ Global Control Tower provides high levels of supply chain transparency; aggregates, completes, and enhances data from a variety of sources; offers visibility into and execution of different aspects of the supply chain; and generates data-driven alerts and analytics that ask deeper questions and deliver meaningful insights.

By leveraging tracking information, the Global Control Tower provides analytics that measures key performance indicators (KPIs) like fleet cycle time, origin/destination dwell time, lane and hauler performance, back orders, freight spend, load optimization, and more. With their rate, equipment, lease, tracking, and invoice data in a central repository that’s accessible 24/7, companies can position themselves for success in any market conditions.